Tungsten Sputtering Targets

Tungsten Sputtering Targets

Tungsten sputtering targets play a crucial role in various modern technological applications. These targets are an essential part of the sputtering process, which is widely used in industries such as electronics, semiconductors, and optics.

The properties of tungsten make it an ideal choice for sputtering targets. Tungsten is known for its high melting point, excellent thermal conductivity, and low vapor pressure. These characteristics allow it to withstand the high temperatures and energetic particle bombardment during the sputtering process without significant degradation.

In the electronics industry, tungsten sputtering targets are used to deposit thin films onto substrates for the fabrication of integrated circuits and microelectronic devices. The precise control of the sputtering process ensures the uniformity and quality of the deposited films, which is critical for the performance and reliability of electronic components.

For example, in the production of flat-panel displays, tungsten thin films deposited using sputtering targets contribute to the conductivity and functionality of the display panels.

In the semiconductor sector, tungsten is used for creating interconnects and barrier layers. The ability to deposit thin and conformal tungsten films helps in reducing electrical resistance and enhancing the device's overall performance.

Optical applications also benefit from tungsten sputtering targets. Tungsten coatings can improve the reflectivity and durability of optical components, such as mirrors and lenses.

The quality and purity of the tungsten sputtering targets are of utmost importance. Even minor impurities can affect the properties and performance of the deposited films. Manufacturers employ strict quality control measures to ensure that the targets meet the demanding requirements of different applications.

Tungsten sputtering targets are indispensable in the advancement of modern technologies, enabling the creation of high-quality thin films that drive the development of electronics, semiconductors, and optics. Their continued improvement and innovation will undoubtedly play a significant role in shaping the future of these industries.

Different Types of Tungsten Sputtering Targets and Their Applications

There are several types of tungsten sputtering targets, each with its unique characteristics and uses.

Pure Tungsten Sputtering Targets: These are composed of pure tungsten and are often used in applications where high melting point, excellent thermal conductivity, and low vapor pressure are essential. They are commonly employed in the semiconductor industry for depositing tungsten films for interconnects and barrier layers. For instance, in the manufacturing of microprocessors, pure tungsten sputtering helps create reliable electrical connections.

Alloyed Tungsten Sputtering Targets: These targets contain tungsten combined with other elements like nickel, cobalt, or chromium. Alloyed tungsten targets are used when specific material properties are needed. An example is in the aerospace industry, where an alloyed tungsten sputtering target might be used to create coatings on turbine components for enhanced heat resistance and wear resistance.

Tungsten Oxide Sputtering Targets: These are used in applications where oxide films are required. They find use in the production of transparent conductive oxides for touchscreen displays and solar cells. The oxide layer helps in improving the electrical conductivity and optical properties of the final product.

Composite Tungsten Sputtering Targets: These consist of tungsten combined with other materials in a composite structure. They are utilized in cases where a combination of properties from both components is desired. For example, in the coating of medical devices, a composite tungsten target might be used to create a biocompatible and durable coating.

The choice of the type of tungsten sputtering target depends on the specific requirements of the application, including the desired film properties, substrate material, and processing conditions.

Tungsten Target Application

Widely used in flat panel displays, solar cells, integrated circuits, automotive glass, microelectronics, memory, X-ray tubes, medical equipment, melting equipment and other products.

Sizes of Tungsten Targets:

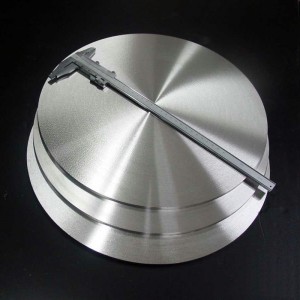

Disc target:

Diameter: 10mm to 360mm

Thickness: 1mm to 10mm

Planar target

Width: 20mm to 600mm

Length: 20mm to 2000mm

Thickness: 1mm to 10mm

Rotary target

Outer diameter: 20mm to 400mm

Wall thickness: 1mm to 30mm

Length: 100mm to 3000mm

Tungsten Sputtering Target Specifications:

Appearance: silver white metal luster

Purity: W≥99.95%

Density: more than 19.1g/cm3

Supply state: Surface polishing, CNC machine processing

Quality standard: ASTM B760-86, GB 3875-83