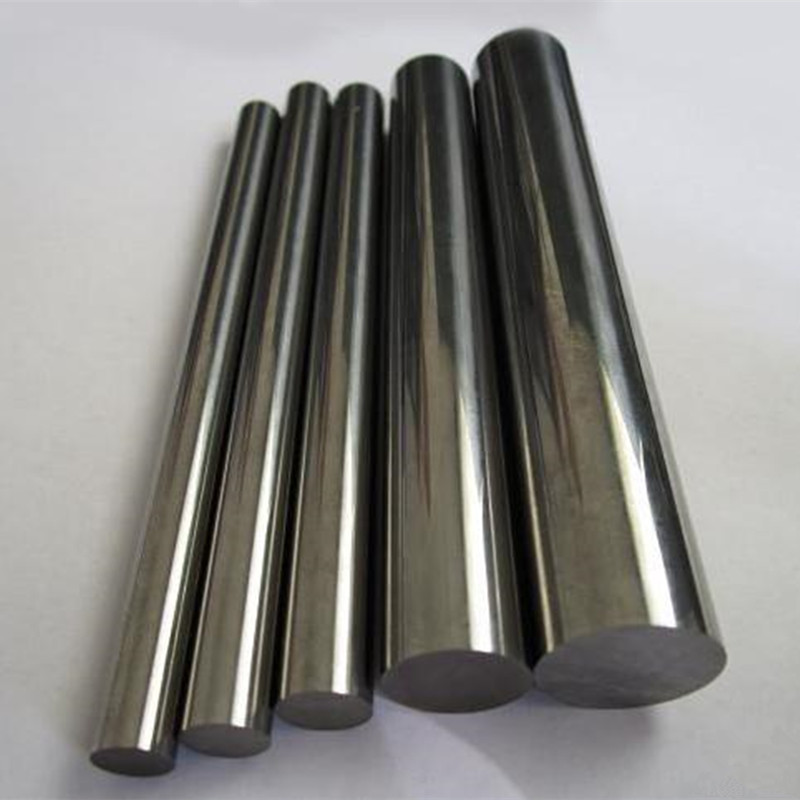

Tungsten Heavy Alloy Rod

Specifications

Tungsten Heavy Alloy Grade:

W90NiFe/W92.5NiFe/W93NiFe/W95NiFe/W97NiFe (Slightly Magnetic).

W90NiCu/W92.5NiCu/W93NiCu/W95NiCu/W97NiCu (Nonmagnetic).

Density: 16.8-18.8g/cm3.

Surface: Machined & Ground.

Standard: ASTM B777.

Diameter: 5.0mm – 80mm.

Length: 50mm – 350mm.

Tungsten High Density Alloy Advantages

High density (up to 65% denser than Lead).

Denser materials exist (pure Tungsten, Gold, platinum group metals) but their use is restricted by availability, workability and cost.

Providing mass where volume space is limited.

Concentrated weight essential where accuracy is required in placement of mass.

Placement of weight in situations where airflow has a significant impact.

Thermal Properties of Tungsten Heavy Alloys

High softening temperature.

Low thermal conductivity and low coefficient of expansion gives the material a high resistance to thermal fatigue.

Excellent soldering erosion resistance to molten aluminum. Strong at high temperatures with high thermal stability.

Tungsten High Density Alloy Mechanical Properties

● High Young's modulus of elasticity. Does not creep when experiencing significant forces, unlike Lead.

● Despite their strength, they remain ductile and resistant to cracking.

● The hardness range of the alloys is typically 20-35 Hardness HRC.

High-Density Tungsten Based Alloy

| Alloy Type(%) | HD17 90W 6Ni 4Cu | HD17D 90W 7Ni 3Fe | HD17.5 92.5W 5.25Ni 2.25Fe | HD17.6 92.5W Balance Ni, Fe, Mo | HD17.7 93W Balance Ni, Fe, Mo | HD18 95W 3.5Ni 1.5Cu | HD18D 95W 3.5Ni 1.5Fe | HD18.5 97W 2.1Ni .9Fe |

| MIL-T-21014 | Class 1 | Class 1 | Class 1 | - | - | Class 3 | Class 3 | Class 4 |

| SAE-AMS-T-21014 | Class 1 | Class 1 | Class 2 | - | - | Class 3 | Class 3 | Class 4 |

| AMS 7725 C | 7725 C | 7725 C | -- | -- | -- | -- | -- | -- |

| ASTM B777-87 | Class 1 | Class 1 | Class 2 | - | - | Class 3 | Class 3 | Class 4 |

| Typical Density (g/cc) | 17.1 | 17.1 | 17.5 | 17.6 | 17.7 | 18 | 18 | 18.5 |

| Typical Density (lbs/in3) | 0.614 | 0.614 | 0.632 | 0.636 | 0.639 | 0.65 | 0.65 | 0.668 |

| Typical Hardness RC | 24 | 25 | 26 | 30 | 32 | 27 | 27 | 28 |

| Ultimate Tensile Strength Min (ksi) | 110,000 | 120,000 | 114,000 | 120,000 | 125,000 | 110,000 | 120,000 | 123,000 |

| 0.2% Offset Yield Strength Min (ksi) | 80,000 | 88,000 | 84,000 | 90,000 | 95,000 | 85,000 | 90,000 | 85,000 |

| Minimum % Elongation (1" gage length) | 6 | 10 | 7 | 4 | 4 | 7 | 7 | 5 |

| Proportional Elastic Limit (PSI) | 45,000 | 52,000 | 46,000 | 55,000 | 60,000 | 45,000 | 44,000 | 45,000 |

| Modulus of Elasticity (x106psi) | 40 x 106 | 45 x 106 | 47 x 106 | 52 x 106 | 53 x 106 | 45 x 106 | 50 x 106 | 53 x 106 |

| Coefficient of Thermal Expansion x10-6/0C (20-400C) | 5.4 | 4.61 | 4.62 | 4.5 | 4.5 | 4.43 | 4.6 | 4.5 |

| Thermal Conductivity (CGS Units) | 0.23 | 0.18 | 0.2 | 0.27 | 0.27 | 0.33 | 0.26 | 0.3 |

| Electrical Conductivity (% IACS) | 14 | 10 | 13 | 14 | 14 | 16 | 13 | 17 |

| Magnetic | No | Slightly | Slightly | Slightly | Slightly | No | Slightly | Slightly |