Top Quality Titanium Pipe Fittings - Pure Titanium Rod Titanium Alloy Bar – Fotma

Top Quality Titanium Pipe Fittings - Pure Titanium Rod Titanium Alloy Bar – Fotma Detail:

Description

Titanium rod is the raw material used to make titanium alloy and titanium metal. It has the characteristics of low density, high strength and good corrosion resistance. In the aerospace industry, titanium rod is widely used in the manufacture of aircraft structural parts and rocket nozzles; in the chemical industry, it is used as a catalyst carrier and a purification device for electrolytes; in the machinery industry, it can be used as a heat exchanger and condenser material.

In the metallurgical industry, titanium rod/bar is mainly used to produce various pure iron, stainless steel, heat-resistant steel and special alloy steel. In addition, it is also used in the manufacture of artificial gemstones and artificial rutile zircon crystals, piezoelectric ceramic sheets for the electronics industry, and precision castings of various shapes.

Pure Titanium Rod / Titanium Alloy Bar Specifications

Titanium Alloy Grade: Gr.5, Gr.23, Ti-6Al-4v-Eli, TI5, BT6,Ti-6al-7Nb.

Commercial pure Titanium Grade: Gr.3, Gr.4 commercially pure.

Diameter Range: Ø5mm, Ø6mm, Ø8mm, Ø12mm, Ø14mm, Ø25mm, Ø30mm, etc.

Tolerance Standard: ISO 286.

Standard: ASTM F67, ASTM F136, ISO 5832.

Available length: 2.5 m ~ 3 m (98.4 ~ 118.1″), or customized.

Straightness: perfect for CNC machining.

All the Titanium and Titanium Alloy rods/bars could be supplied with customized diameter or length, to fit Customer’s requirements.

Features of titanium alloy rods: Excellent elasticity, high strength and homogeneous microstructure.

Titanium Grade Available

| ASTM B265 | GB/T 3620.1 | JIS H4600 | Elemental content (wt%) | ||||||

| N,Max | C,Max | H,Max | Fe,Max | O,Max | Others | ||||

| PureTitanium | Gr.1 | TA1 | Class 1 | 0.03 | 0.08 | 0.015 | 0.20 | 0.18 | - |

| Gr.2 | TA2 | Class 2 | 0.03 | 0.08 | 0.015 | 0.30 | 0.25 | - | |

| Gr.3 | TA3 | Class 3 | 0.05 | 0.08 | 0.015 | 0.30 | 0.35 | - | |

| Gr.4 | TA4 | Class 4 | 0.05 | 0.08 | 0.015 | 0.50 | 0.40 | - | |

| TitaniumAlloy | Gr.5 | TC4 Ti-6Al-4V | Class 60 | 0.05 | 0.08 | 0.015 | 0.40 | 0.20 | Al:5.5-6.75; V:3.5-4.5 |

| Gr.7 | TA9 | Class 12 | 0.03 | 0.08 | 0.015 | 0.30 | 0.25 | Pd:0.12-0.25 | |

| Gr.11 | TA9-1 | Class 11 | 0.03 | 0.08 | 0.015 | 0.20 | 0.18 | Pd:0.12-0.25 | |

| Gr.23 | TC4 ELI | Class 60E | 0.03 | 0.08 | 0.0125 | 0.25 | 0.13 | Al:5.5-6.5; V:3.5-4.5 | |

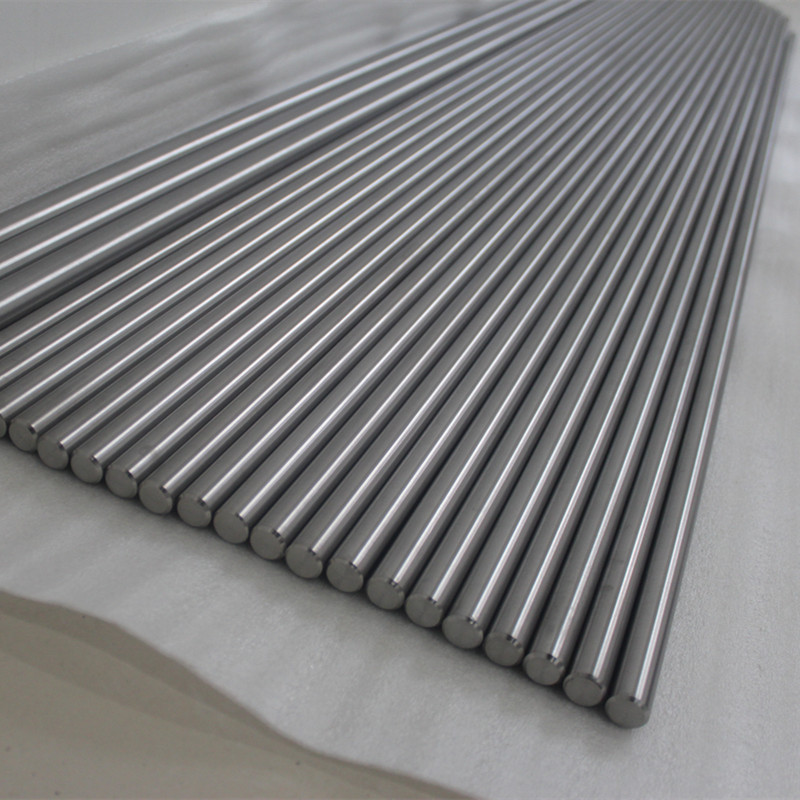

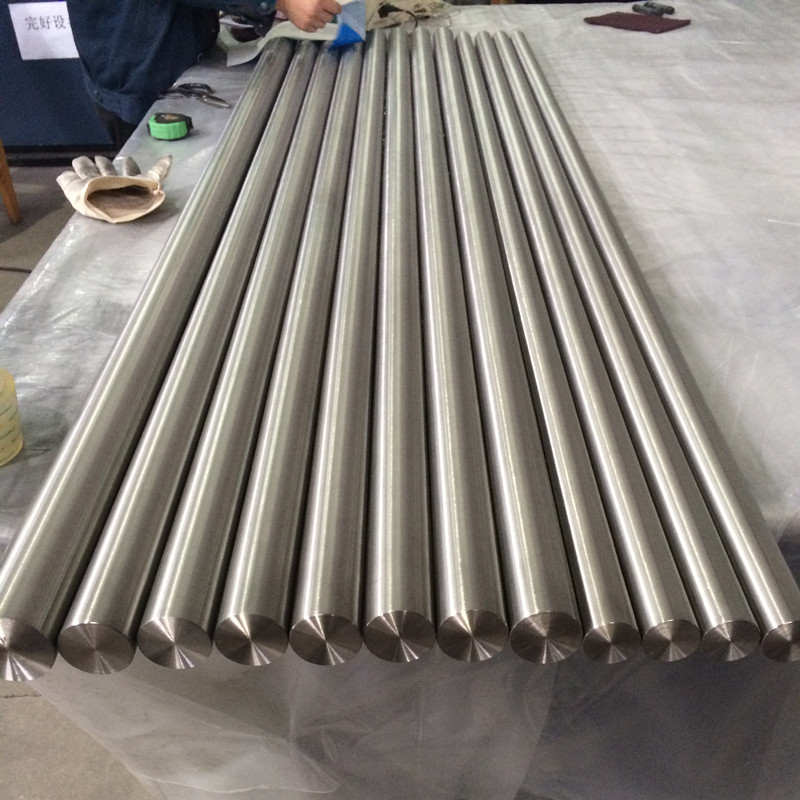

Product detail pictures:

Related Product Guide:

Being supported by an advanced and specialist IT team, we could give technical support on pre-sales & after-sales services for Top Quality Titanium Pipe Fittings - Pure Titanium Rod Titanium Alloy Bar – Fotma , The product will supply to all over the world, such as: Roman, Ukraine, Pakistan, We always insist on the management tenet of "Quality is First, Technology is Basis, Honesty and Innovation".We are able to develop new products continuously to a higher level to satisfy different needs of customers.

Speaking of this cooperation with the Chinese manufacturer, I just want to say"well dodne", we are very satisfied.