Welcome to Fotma Alloy!

Silicon Molybdenum MoSi2 Heating Elements – Fotma

Silicon Molybdenum MoSi2 Heating Elements – Fotma Detail:

Description

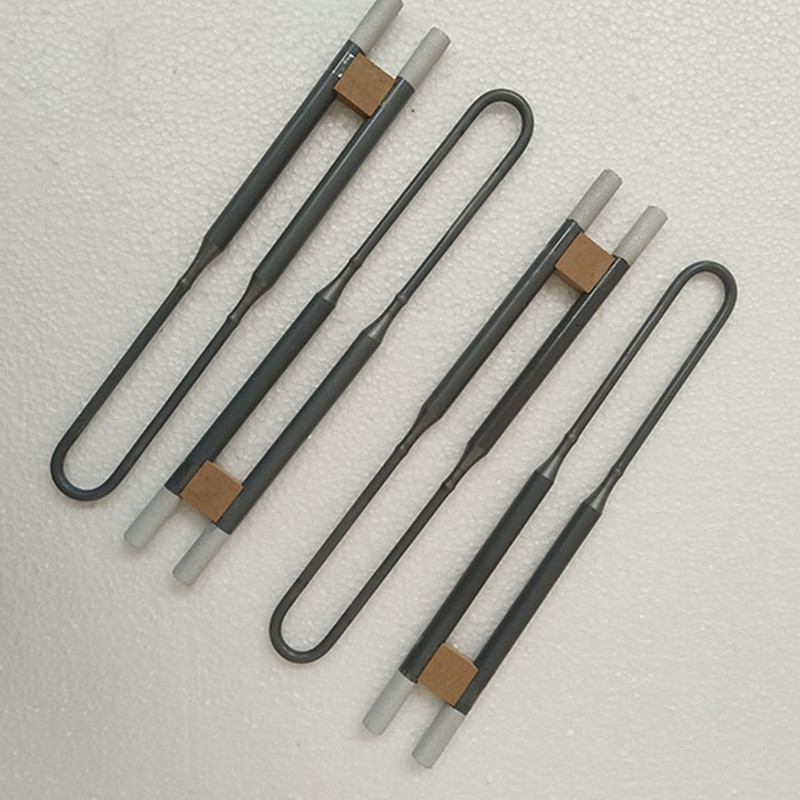

Silicon molybdenum rod / MoSi2 heating element for heating furnace, 1800C High Purity Dental molybdenum disilicide heating element for dental ceramic furnace

Furnace Heating Element

Standard Size for Electric MoSi2 Heater

M1700 type (d/c): dia3/6, dia4/9, dia6/12, dia9/18, dia12/24.

M1800 type (d/c): dia3/6, dia4/9, dia6/12, dia9/18, dia12/24.

MoSi2 Heater Advantages

Technical Data of MoSi2 Heating Elements

| Density | Bending Strength | Hardness | Apparent Porosity | Water Absorption | Elongation | Fracture Toughness | Compressive Strength |

| 5.8g/cm3 | 350Mpa | 12.0Gpa | ±2% | 0 | 4% | 4.5Mpa.m1/2 | 650Mpa |

The Influence of Operation Temperature on the Heater Surface in Different Atmosphere

| Atmosphere | 1700 Type | 1800 Type |

| Air | 1700 | 1800 |

| N2 | 1600 | 1700 |

| He | 1600 | 1700 |

| -80°C Dry H2 | 1150 | 1150 |

| -20°C Wet H2 | 1450 | 1450 |

| 10%CO2, 50%CO, 15%H2 | 1600 | 1700 |

Product detail pictures:

Related Product Guide:

We aim to find out quality disfigurement from the production and supply the best service to domestic and overseas customers wholeheartedly for Silicon Molybdenum MoSi2 Heating Elements – Fotma , The product will supply to all over the world, such as: Netherlands, United Kingdom, Armenia, We can meet the various needs of customers at home and abroad. We welcome new and old customers to come to consult & negotiate with us. Your satisfaction is our motivation! Allow us to work together to write a brilliant new chapter!

The customer service staff's attitude is very sincere and the reply is timely and very detailed, this is very helpful for our deal,thank you.

Write your message here and send it to us