Low MOQ for Machining Metal - CMC CuMoCu Heat Sink – Fotma

Low MOQ for Machining Metal - CMC CuMoCu Heat Sink – Fotma Detail:

CMC CuMoCu Material Application

Low Expansion Layers and Thermal Paths for Heat Sinks, Lead Frames, Multi-layer Printed Circuit Boards (PCBs), etc.

Heat sink material on aircraft, heat sink material on radar.

CMC Heat Sink Advantages

1. CMC composite adopts a new process, multilayer copper-molybdenum-copper, the bonding between copper and molybdenum is tight, there is no gap, and there will be no interface oxidation during subsequent hot rolling and heating, so that the bonding strength between molybdenum and copper is excellent, So that the finished material has the lowest thermal expansion coefficient and the best thermal conductivity;

2. The molybdenum-copper ratio of CMC is very good, and the deviation of each layer is controlled within 10%; SCMC material is a multi-layer composite material. The structural composition of the material from top to bottom is: copper sheet – molybdenum sheet – copper sheet – molybdenum sheet… copper sheet, it can be composed of 5 layers, 7 layers or even more layers. Compared with CMC, SCMC will have the lowest thermal expansion coefficient and the highest thermal conductivity.

Grade of CMC Cu-Mo-Cu Materials

| Grade | Density g/cm3 | Coefficient of thermal Expansion ×10-6 (20℃) | Thermal conductivity W/(M·K) |

| CMC111 | 9.32 | 8.8 | 305(XY)/250(Z) |

| CMC121 | 9.54 | 7.8 | 260(XY)/210(Z) |

| CMC131 | 9.66 | 6.8 | 244(XY)/190(Z) |

| CMC141 | 9.75 | 6 | 220(XY)/180(Z) |

| CMC13/74/13 | 9.88 | 5.6 | 200(XY)/170(Z) |

| Material | Wt% Molybdenum Content | g/cm3 Density | Thermal conductivity at 25℃ | Coefficient of thermal Expansion at 25℃ |

| S-CMC | 5 | 9.0 | 362 | 14.8 |

| 10 | 9.0 | 335 | 11.8 | |

| 13.3 | 9.1 | 320 | 10.9 | |

| 20 | 9.2 | 291 | 7.4 |

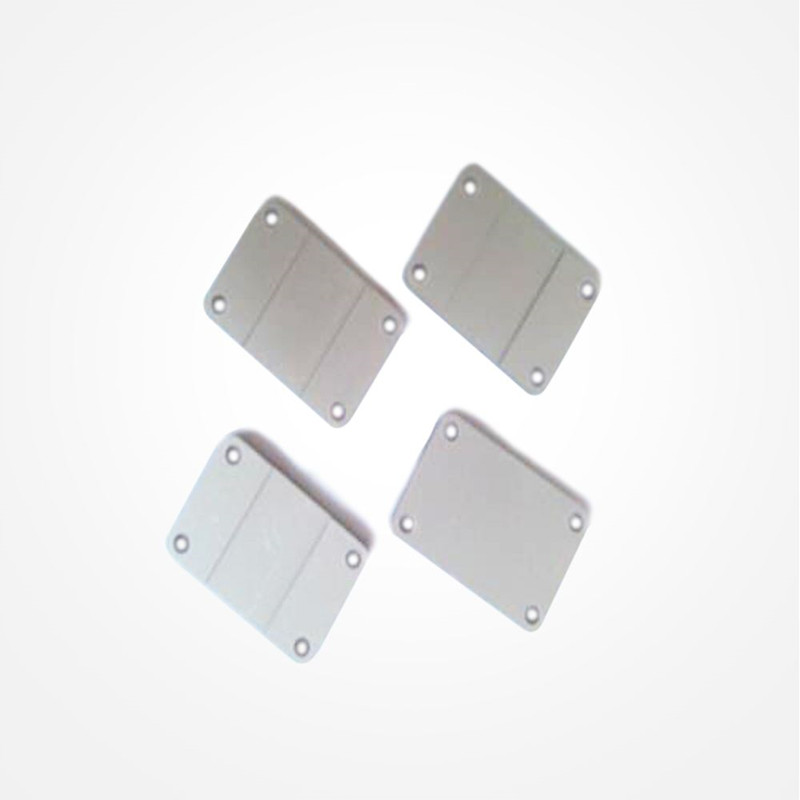

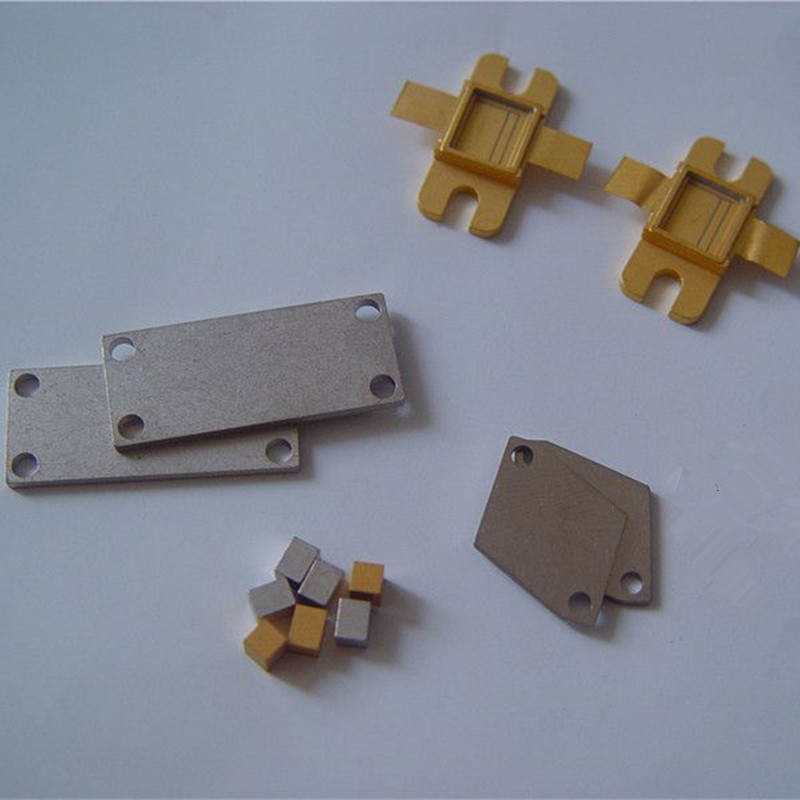

Product detail pictures:

Related Product Guide:

We always stick to the principle "Quality First, Prestige Supreme". We are fully committed to providing our clients with competitively priced quality products, prompt delivery and professional service for Low MOQ for Machining Metal - CMC CuMoCu Heat Sink – Fotma , The product will supply to all over the world, such as: Uganda, Leicester, Brisbane, So that you can utilize the resource from the expanding info in international trade, we welcome shoppers from everywhere on-line and offline. In spite of the good quality solutions we provide, effective and satisfying consultation service is supplied by our professional after-sale service team. Product lists and detailed parameters and any other info weil be sent to you timely for your inquiries. So you should make contact with us by sending us emails or call us if you have any questions about our corporation. ou may also get our address info from our web page and come to our company to get a field survey of our merchandise. We've been confident that we have been going to share mutual achievement and create strong co-operation relations with our companions in this marketplace. We're searching forward for your inquiries.

The customer service staff's answer is very meticulous, the most important is that the product quality is very good, and packaged carefully, shipped quickly!