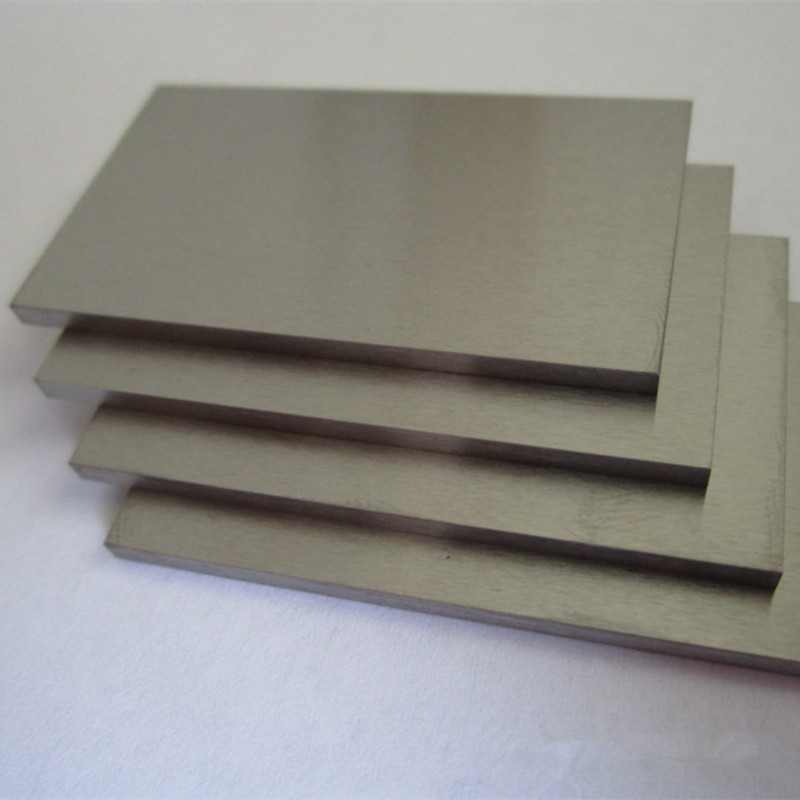

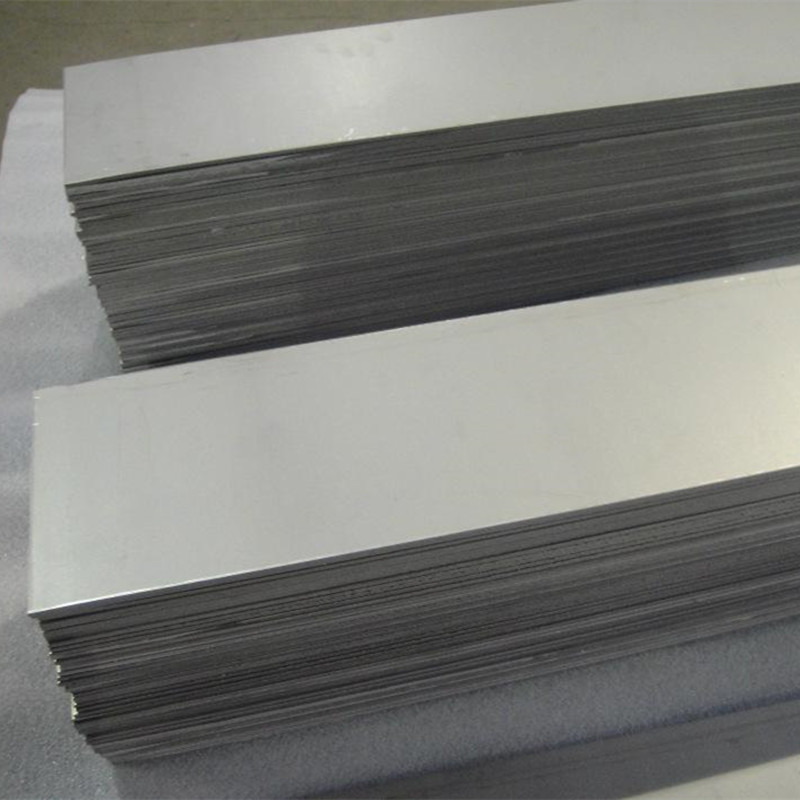

High Quality Tungsten Casting - Pure Tungsten Plate Tungsten Sheet – Fotma

High Quality Tungsten Casting - Pure Tungsten Plate Tungsten Sheet – Fotma Detail:

Purity 99.95% Tungsten Plates Tungsten Sheets Brief Introduction

1. Material Grade: W1.

2. Tungsten purity: 99.95%.

3. Density: no less than 19.1g/cm3.

4. Size: 0.1mm~100mm thickness x 50-600mm width x 50-1000mm length.

5. Surface: Black, chemical cleaned or machined/ground.

6. Tungsten Sheets Feature: High melting point, High-density, high temperature oxidation resistance, long service life, resistance to corrosion, High quality, workability.

7. Applications of pure tungsten plate / tungsten sheet: Tungsten plate mainly used in manufacturing electric light source and electric vacuum parts, boats, heatshield and heat bodies in high temperature furnace , Medical diagnosis and treatment equipment ;as a means of high temperature heating element and high temperature structure parts; to product tungsten spiral for vacuum evaporation and making tungsten sputtering target.

Tungsten Sheet Size (max mm)

| Thickness | Width | Length |

| 0.05-0.15 | 100 | 200 |

| 0.15-0.20 | 205 | 1000 |

| 0.20-0.25 | 300 | 1000 |

| 0.25-0.30 | 330 | 1000 |

| 0.30-0.50 | 350 | 800 |

| 0.50-0.80 | 300 | 600 |

| 0.80-1.0 | 300 | 500 |

| 1.0-1.50 | 400 | 650 |

| 1.50-3.0 | 300 | 600 |

| >3.0 | 300 | L |

Tungsten Material Properties

There is an increasing demand of tungsten material from the electronics, nuclear, and aerospace industries for materials that maintain reliability under ever-increasing temperature conditions. Because its properties meet these requirements, tungsten also is experiencing an increasing demand.

Characteristics that support the demand for tungsten in many electronics applications are its:

● Strength and stiffness at high temperatures.

● Good thermal conductivity.

● Low thermal expansion.

● Low emissivity.

Polished Tungsten Plate Size (max mm)

| Thickness | Width | Length |

| 3.0-4.0 | 250 | 400 |

| 4.0-6.0 | 300 | 600 |

| 6.0-8.0 | 300 | 800 |

| 8.0-10.0 | 300 | 750 |

| 10.0-14.0 | 200 | 650 |

| >14.0 | 200 | 500 |

Pure Tungsten Plate / Tungsten Sheet Usages

Furnace parts, Semiconductor Base Plates, Components for Electron Tubes, Emission Cathodes for Electron Beam Evaporation, Cathodes and Anodes for Ion Implantation, Tubes / Boats for Sintering of Capacitors, Targets for X-ray Diagnostics, Crucibles, Heating Elements, X-ray Radiation Shielding, Sputtering Targets, Electrodes.

Product detail pictures:

Related Product Guide:

We have been experienced manufacturer. Wining the majority of your crucial certifications of its market for High Quality Tungsten Casting - Pure Tungsten Plate Tungsten Sheet – Fotma , The product will supply to all over the world, such as: Slovak Republic, US, Hongkong, We also provide OEM service that caters to your specific needs and requirements. With a strong team of experienced engineers in hose design and development, we value every opportunity to provide best products for our customers.

The goods we received and the sample sales staff display to us have the same quality, it is really a creditable manufacturer.