Welcome to Fotma Alloy!

High Quality for Molybdenum Heating Element - Silicon Molybdenum MoSi2 Heating Elements – Fotma

High Quality for Molybdenum Heating Element - Silicon Molybdenum MoSi2 Heating Elements – Fotma Detail:

Description

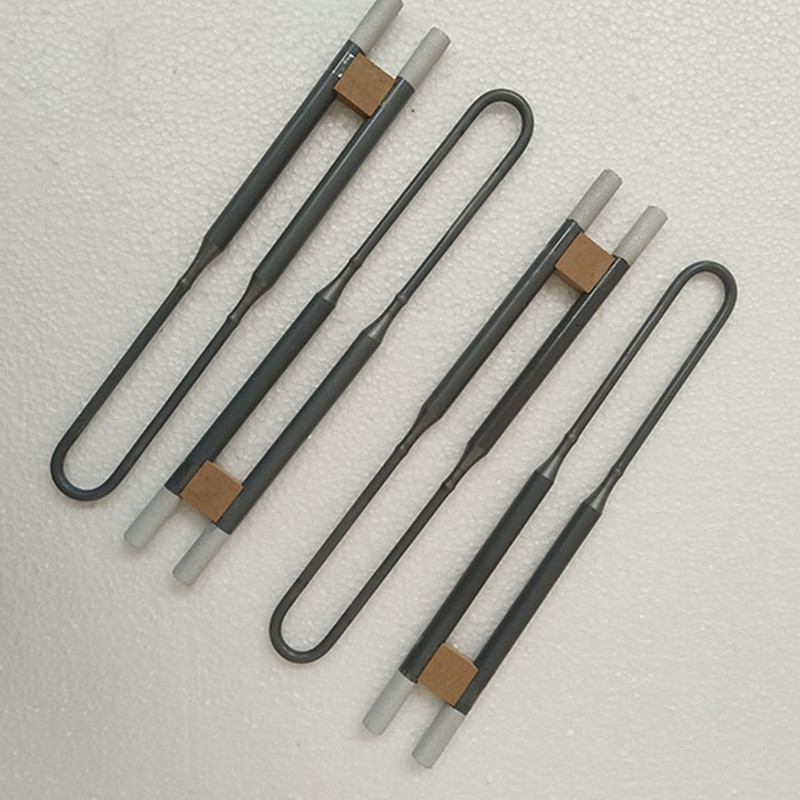

Silicon molybdenum rod / MoSi2 heating element for heating furnace, 1800C High Purity Dental molybdenum disilicide heating element for dental ceramic furnace

Furnace Heating Element

Standard Size for Electric MoSi2 Heater

M1700 type (d/c): dia3/6, dia4/9, dia6/12, dia9/18, dia12/24.

M1800 type (d/c): dia3/6, dia4/9, dia6/12, dia9/18, dia12/24.

MoSi2 Heater Advantages

Technical Data of MoSi2 Heating Elements

| Density | Bending Strength | Hardness | Apparent Porosity | Water Absorption | Elongation | Fracture Toughness | Compressive Strength |

| 5.8g/cm3 | 350Mpa | 12.0Gpa | ±2% | 0 | 4% | 4.5Mpa.m1/2 | 650Mpa |

The Influence of Operation Temperature on the Heater Surface in Different Atmosphere

| Atmosphere | 1700 Type | 1800 Type |

| Air | 1700 | 1800 |

| N2 | 1600 | 1700 |

| He | 1600 | 1700 |

| -80°C Dry H2 | 1150 | 1150 |

| -20°C Wet H2 | 1450 | 1450 |

| 10%CO2, 50%CO, 15%H2 | 1600 | 1700 |

Product detail pictures:

Related Product Guide:

Using a total scientific good quality management process, superior high quality and excellent faith, we get great name and occupied this field for High Quality for Molybdenum Heating Element - Silicon Molybdenum MoSi2 Heating Elements – Fotma , The product will supply to all over the world, such as: Austria, Finland, Kuwait, We have a large share in global market. Our company has strong economic strength and offers excellent sale service. We have established faith, friendly, harmonious business relationship with customers in different countries. , such as Indonesia, Myanmar, Indi and other Southeast Asian countries and European, African and Latin American countries.

We have been looking for a professional and responsible supplier, and now we find it.

Write your message here and send it to us