Factory supplied Machining Supplier - CMC CuMoCu Heat Sink – Fotma

Factory supplied Machining Supplier - CMC CuMoCu Heat Sink – Fotma Detail:

CMC CuMoCu Material Application

Low Expansion Layers and Thermal Paths for Heat Sinks, Lead Frames, Multi-layer Printed Circuit Boards (PCBs), etc.

Heat sink material on aircraft, heat sink material on radar.

CMC Heat Sink Advantages

1. CMC composite adopts a new process, multilayer copper-molybdenum-copper, the bonding between copper and molybdenum is tight, there is no gap, and there will be no interface oxidation during subsequent hot rolling and heating, so that the bonding strength between molybdenum and copper is excellent, So that the finished material has the lowest thermal expansion coefficient and the best thermal conductivity;

2. The molybdenum-copper ratio of CMC is very good, and the deviation of each layer is controlled within 10%; SCMC material is a multi-layer composite material. The structural composition of the material from top to bottom is: copper sheet – molybdenum sheet – copper sheet – molybdenum sheet… copper sheet, it can be composed of 5 layers, 7 layers or even more layers. Compared with CMC, SCMC will have the lowest thermal expansion coefficient and the highest thermal conductivity.

Grade of CMC Cu-Mo-Cu Materials

| Grade | Density g/cm3 | Coefficient of thermal Expansion ×10-6 (20℃) | Thermal conductivity W/(M·K) |

| CMC111 | 9.32 | 8.8 | 305(XY)/250(Z) |

| CMC121 | 9.54 | 7.8 | 260(XY)/210(Z) |

| CMC131 | 9.66 | 6.8 | 244(XY)/190(Z) |

| CMC141 | 9.75 | 6 | 220(XY)/180(Z) |

| CMC13/74/13 | 9.88 | 5.6 | 200(XY)/170(Z) |

| Material | Wt% Molybdenum Content | g/cm3 Density | Thermal conductivity at 25℃ | Coefficient of thermal Expansion at 25℃ |

| S-CMC | 5 | 9.0 | 362 | 14.8 |

| 10 | 9.0 | 335 | 11.8 | |

| 13.3 | 9.1 | 320 | 10.9 | |

| 20 | 9.2 | 291 | 7.4 |

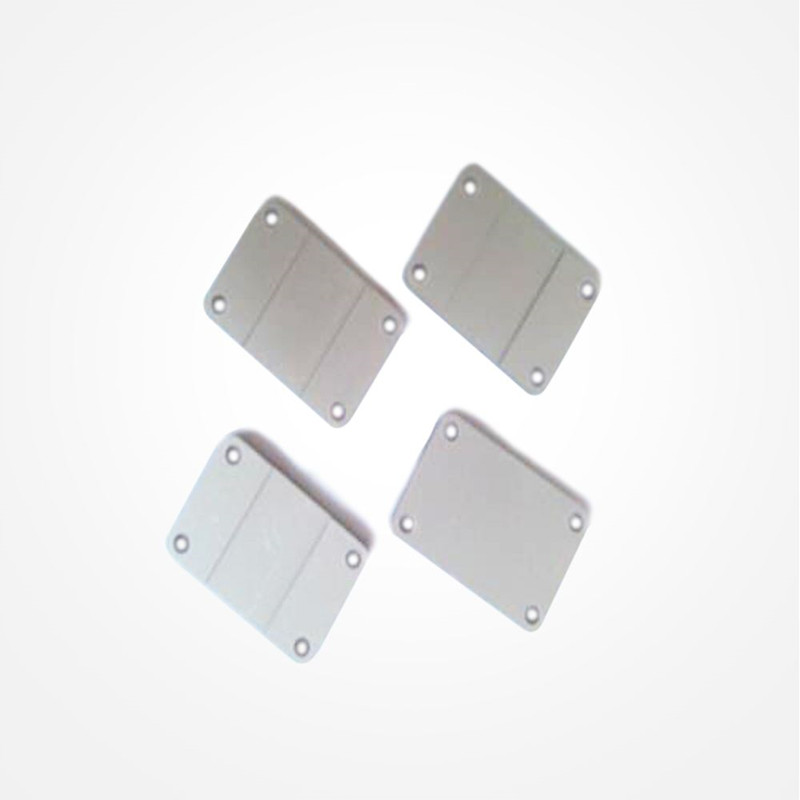

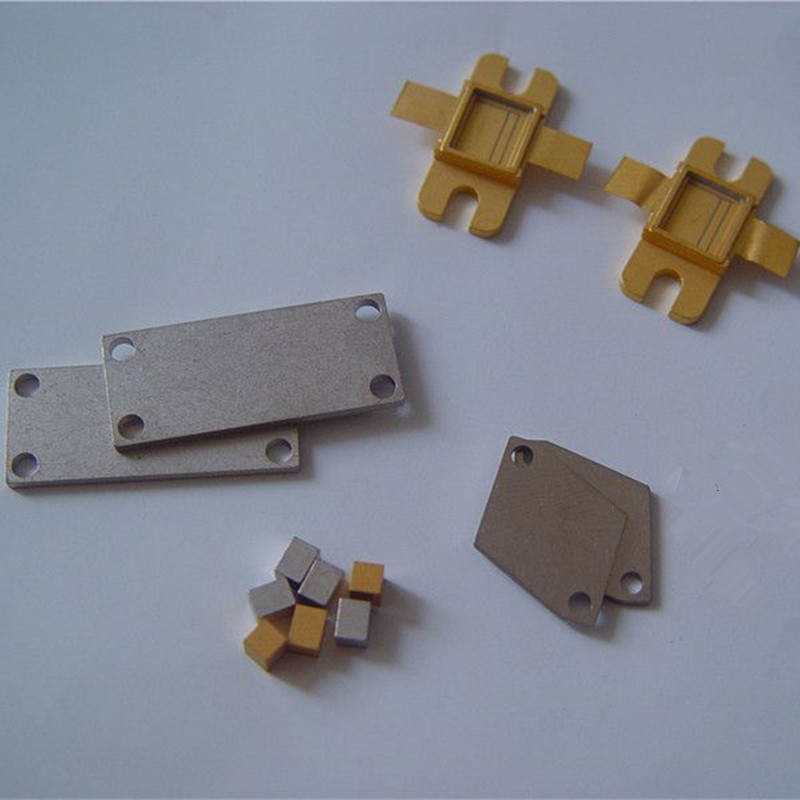

Product detail pictures:

Related Product Guide:

Our advancement depends over the superior machines, exceptional talents and continually strengthened technology forces for Factory supplied Machining Supplier - CMC CuMoCu Heat Sink – Fotma , The product will supply to all over the world, such as: Rome, Yemen, San Francisco, We solution have passed through the national skilled certification and been well received in our key industry. Our specialist engineering team will often be ready to serve you for consultation and feedback. We are able to also provide you with no cost samples to meet your needs. Best efforts will be produced to offer you the very best service and solutions. For anyone who is considering our business and solutions, please speak to us by sending us emails or get in touch with us right away. As a way to know our products and enterprise. lot more, you'll be able to come to our factory to find out it. We will constantly welcome guests from around the globe to our firm. o build enterprise. elations with us. Please really feel absolutely free to make contact with us for small business and we believe we will share the top trading practical experience with all our merchants.

The manufacturer gave us a big discount under the premise of ensuring the quality of products, thank you very much, we will select this company again.