Factory For Tungsten Copper Electrodes - Tungsten Sputtering Targets – Fotma

Factory For Tungsten Copper Electrodes - Tungsten Sputtering Targets – Fotma Detail:

Characteristics of Tungsten Sputtering Targets

1) High purity, the purity of the target after sintering and forging can usually be higher than 99.95%. Generally speaking, under the condition that other conditions remain unchanged, the higher the purity of the target material, the better the electrical properties of the resulting coating, and the less likely the corresponding circuit is to be short-circuited or damaged.

2) The cost is relatively reasonable, and the speed of direct pressing by powder metallurgy is faster, which can effectively shorten the production cycle and thus reduce the cost.

3) High density, the target density after sintering and forging can reach more than 19.1g/cm³.

4) The deflection strength is high, and the composition and structure of the finished target produced by ultra-fine pure tungsten powder are relatively uniform and consistent.

5) Good thermochemical stability, not prone to volume expansion or contraction, chemical reaction with other substances, etc.

6) Low resistance, will not make the circuit generate unnecessary energy.

In addition, it has the characteristics of high melting point, high elasticity, low expansion coefficient, low vapor pressure, non-toxic and non-radioactive

Tungsten Target Application

Widely used in flat panel displays, solar cells, integrated circuits, automotive glass, microelectronics, memory, X-ray tubes, medical equipment, melting equipment and other products.

Sizes of Tungsten Targets:

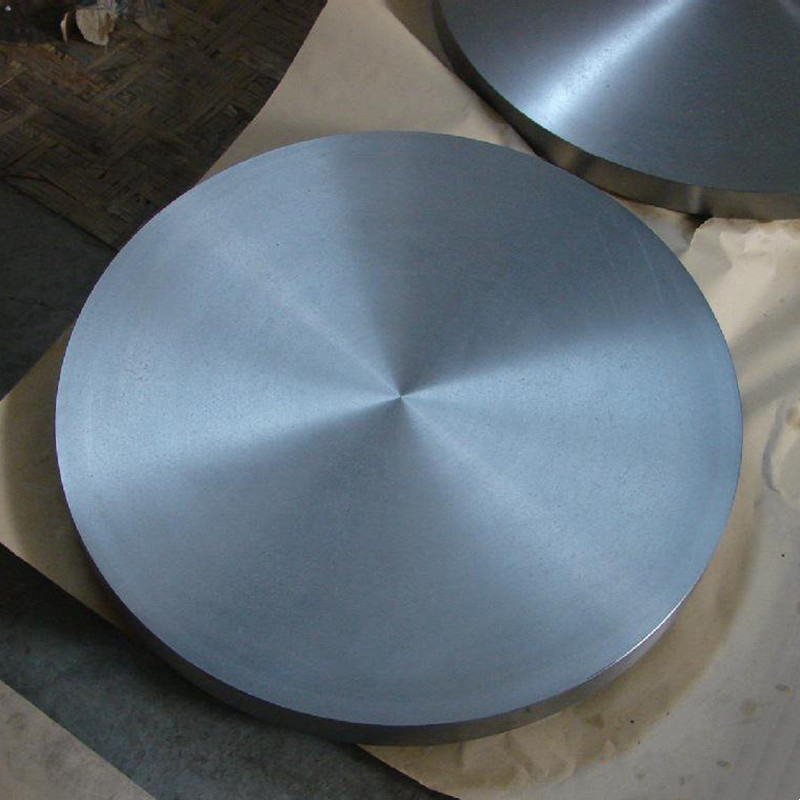

Disc target:

Diameter: 10mm to 360mm

Thickness: 1mm to 10mm

Planar target

Width: 20mm to 600mm

Length: 20mm to 2000mm

Thickness: 1mm to 10mm

Rotary target

Outer diameter: 20mm to 400mm

Wall thickness: 1mm to 30mm

Length: 100mm to 3000mm

Tungsten Sputtering Target Specifications:

Appearance: silver white metal luster

Purity: W≥99.95%

Density: more than 19.1g/cm3

Supply state: Surface polishing, CNC machine processing

Quality standard: ASTM B760-86, GB 3875-83

Product detail pictures:

Related Product Guide:

Good quality comes to start with; service is foremost; organization is cooperation" is our enterprise philosophy which is regularly observed and pursued by our firm for Factory For Tungsten Copper Electrodes - Tungsten Sputtering Targets – Fotma , The product will supply to all over the world, such as: Tunisia, Singapore, Ukraine, The best and original quality for spare parts is a most important factor for transportation. We may stick on supplying original and good quality parts even a little profit earned. God will bless us to do kindness business forever.

The supplier abide the theory of "quality the basic, trust the first and management the advanced" so that they can ensure a reliable product quality and stable customers.