Competitive Price for Machining Component - CMC CuMoCu Heat Sink – Fotma

Competitive Price for Machining Component - CMC CuMoCu Heat Sink – Fotma Detail:

CMC CuMoCu Material Application

Low Expansion Layers and Thermal Paths for Heat Sinks, Lead Frames, Multi-layer Printed Circuit Boards (PCBs), etc.

Heat sink material on aircraft, heat sink material on radar.

CMC Heat Sink Advantages

1. CMC composite adopts a new process, multilayer copper-molybdenum-copper, the bonding between copper and molybdenum is tight, there is no gap, and there will be no interface oxidation during subsequent hot rolling and heating, so that the bonding strength between molybdenum and copper is excellent, So that the finished material has the lowest thermal expansion coefficient and the best thermal conductivity;

2. The molybdenum-copper ratio of CMC is very good, and the deviation of each layer is controlled within 10%; SCMC material is a multi-layer composite material. The structural composition of the material from top to bottom is: copper sheet – molybdenum sheet – copper sheet – molybdenum sheet… copper sheet, it can be composed of 5 layers, 7 layers or even more layers. Compared with CMC, SCMC will have the lowest thermal expansion coefficient and the highest thermal conductivity.

Grade of CMC Cu-Mo-Cu Materials

| Grade | Density g/cm3 | Coefficient of thermal Expansion ×10-6 (20℃) | Thermal conductivity W/(M·K) |

| CMC111 | 9.32 | 8.8 | 305(XY)/250(Z) |

| CMC121 | 9.54 | 7.8 | 260(XY)/210(Z) |

| CMC131 | 9.66 | 6.8 | 244(XY)/190(Z) |

| CMC141 | 9.75 | 6 | 220(XY)/180(Z) |

| CMC13/74/13 | 9.88 | 5.6 | 200(XY)/170(Z) |

| Material | Wt% Molybdenum Content | g/cm3 Density | Thermal conductivity at 25℃ | Coefficient of thermal Expansion at 25℃ |

| S-CMC | 5 | 9.0 | 362 | 14.8 |

| 10 | 9.0 | 335 | 11.8 | |

| 13.3 | 9.1 | 320 | 10.9 | |

| 20 | 9.2 | 291 | 7.4 |

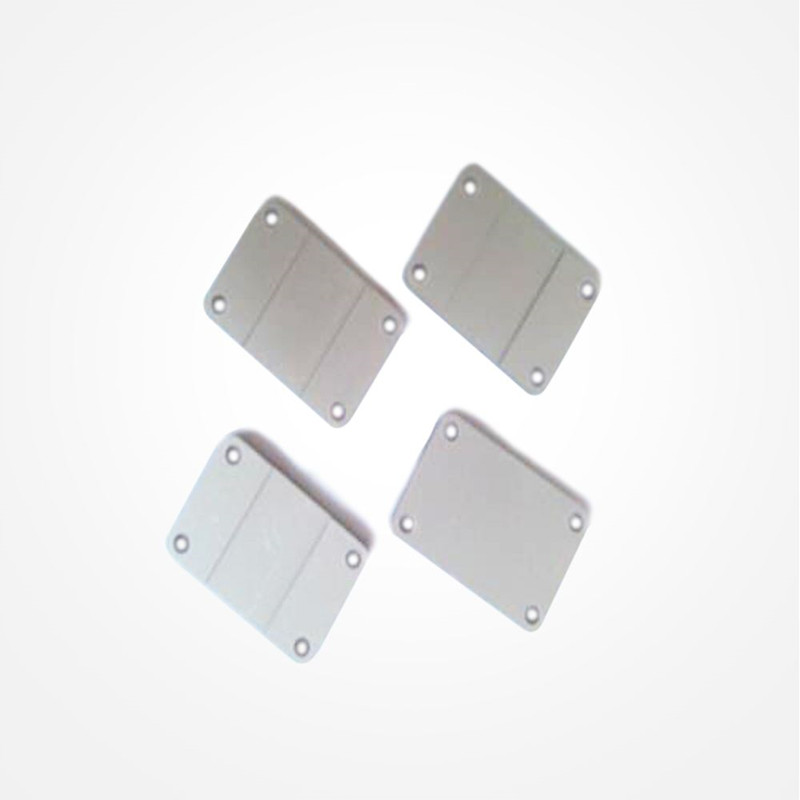

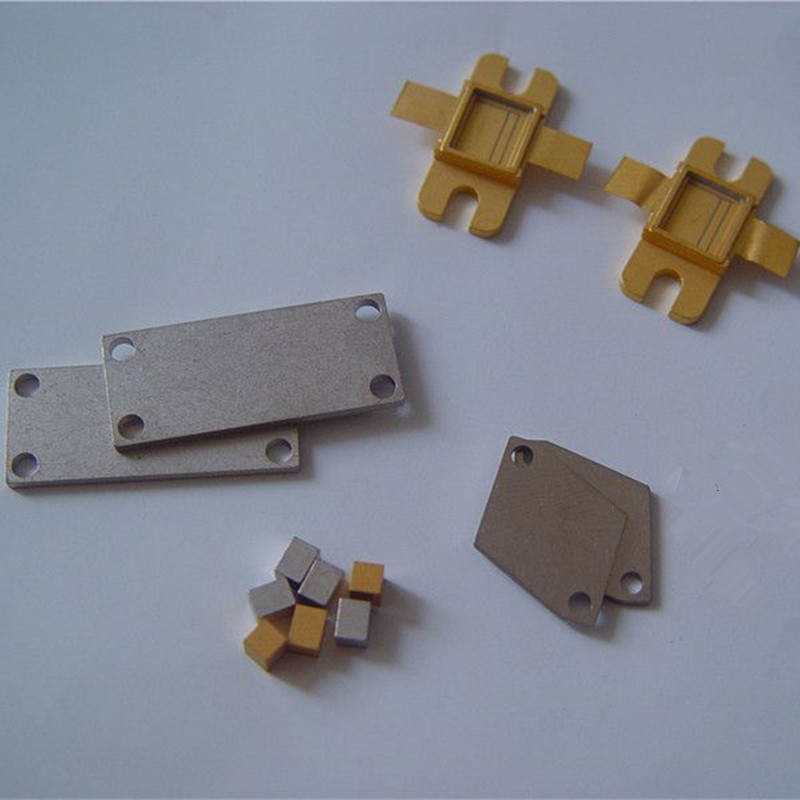

Product detail pictures:

Related Product Guide:

With a positive and progressive attitude to customer's curiosity, our organization repeatedly improves our products top quality to meet the wants of consumers and further focuses on safety, reliability, environmental necessities, and innovation of Competitive Price for Machining Component - CMC CuMoCu Heat Sink – Fotma , The product will supply to all over the world, such as: Nigeria, Johor, Tajikistan, We aim to build a famous brand which can influence a certain group of people and light up the whole world. We want our staff to realize self-reliance, then achieve financial freedom, lastly obtain time and spiritual freedom. We do not focus on how much fortune we can make, instead we aim to obtain high reputation and be recognized for our goods. As a result, our happiness comes from our clients satisfaction rather than how much money we earn. Ours team will do best for you personally always.

Product quality is good, quality assurance system is complete, every link can inquire and solve the problem timely!