Big discounting N06625 - Boron Nitride Ceramic Products – Fotma

Big discounting N06625 - Boron Nitride Ceramic Products – Fotma Detail:

Introduction of boron nitride ceramic products

This boron nitride ceramic product adopts the international advanced vacuum hot-pressing sintering process, with the industry’s leading technical support, to ensure that the material has excellent mechanical, chemical, electrical and thermal properties, and is suitable for a series of high-performance industrial applications. According to industry needs, we can also provide boron nitride ceramic products with high purity and different binders, complete solutions, covering a variety of industry applications and customized profiles.

Boron Nitride Ceramic Applications

● High temperature furnace insulation parts, thermocouple protection tube.

● Amorphous nozzle and powder metal atomizing nozzle.

● High temperature mechanical components, such as bearings, valves and gaskets, etc.

● Molten metal crucible or mold.

● Horizontal continuous casting separation ring.

● Muffle kiln and crucible for nitride and Sialon firing.

● P-type diffusion source in the semiconductor industry.

● MOCVD regulator and its parts.

● Casting and rolling parts.

Features and Advantages of Boron Nitride Ceramic Products

1. Excellent high temperature resistance (use temperature can be ≥ 2000℃ under vacuum and inert atmosphere).

2. High thermal conductivity.

3. Excellent thermal shock resistance and low thermal expansion performance.

4. Excellent electrical insulation performance at high temperatur.

5. High resistance to molten metal, slag, glass.

6. High corrosion and wear resistance.

7. Easy to machine, can be processed according to needs to get the required shape and size.

Ceramic Products Processing Suggestions

Boron nitride ceramic materials have excellent machining properties and can be processed into complex shapes with very small tolerances as required. The following matters should be paid attention to in the processing of boron nitride ceramic materials:

Boron nitride ceramic materials can be processed with standard high-speed steel cutting tools. For the processing of harder PBN-E and composite materials, cemented carbide tools or diamond tools are recommended.

Grinding can be carried out as required, and standard taps and dies can be used to machine threads.

The machining process should always be kept dry, without the use of cutting oil and coolant.

Cutting tools should be sharp and clean, and do not use cutting tools with negative inclination.

When processing materials, be careful when jamming and clamping to avoid excessive pressure. Down-milling technology should be used to prevent missing edges and corners.

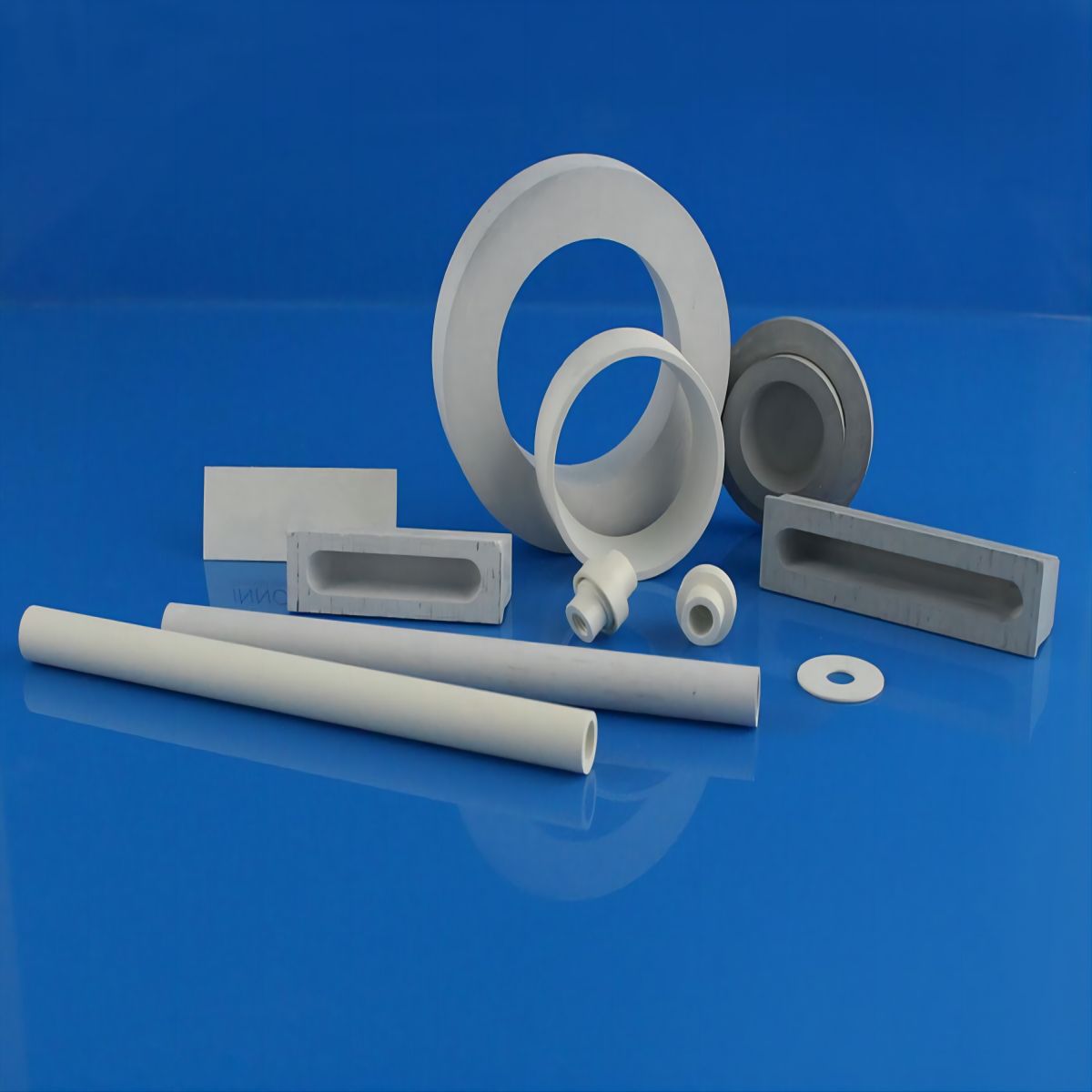

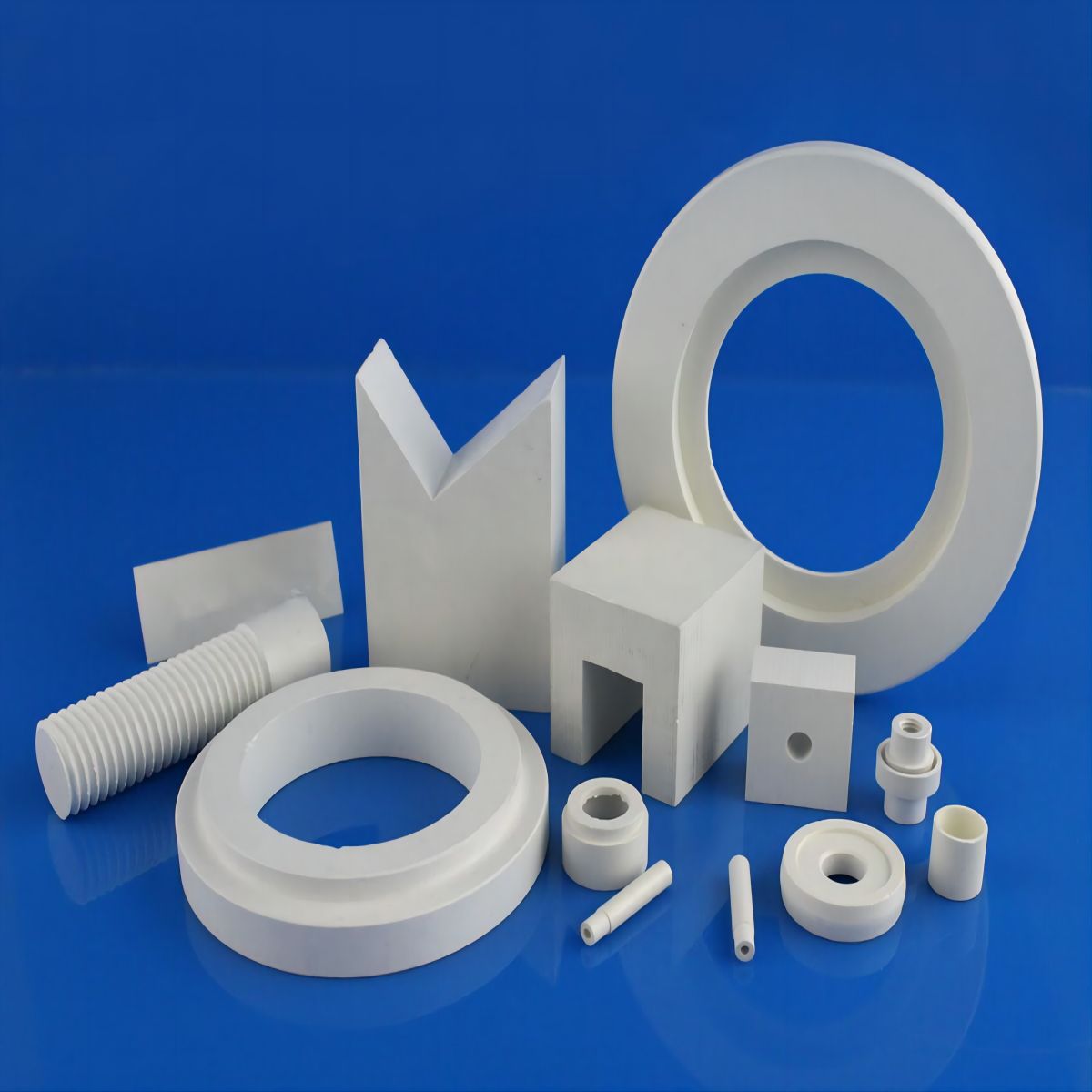

Product detail pictures:

Related Product Guide:

Fast and superior quotations, informed advisers to help you choose the correct merchandise that suits all your requirements, a short generation time, responsible quality control and different services for paying and shipping affairs for Big discounting N06625 - Boron Nitride Ceramic Products – Fotma , The product will supply to all over the world, such as: Haiti, Barcelona, Turkey, Our products are very popular in the word, like South American, Africa, Asia and so on. Companies to "create first-class products" as the goal, and strive to deliver customers with high quality solutions, present high-quality after-sales service and technical support, and customer mutual benefit, create a better career and future!

The goods we received and the sample sales staff display to us have the same quality, it is really a creditable manufacturer.